INFINITE POSSIBILITIES FOR SURFACE FINISHING

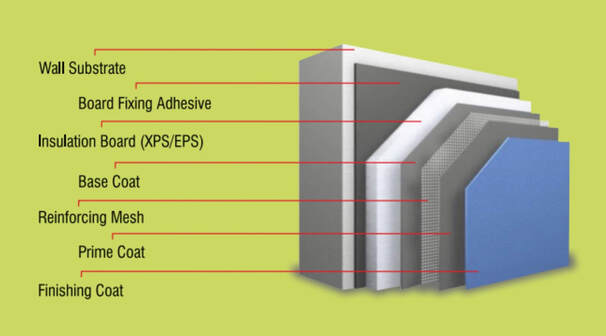

Application Methodology of EIFS (Exterior Insulation & Finishing System) with INSUboard

The walls ( brick/ concrete) should be properly leveled and plastered and free from dust, fungal growth, etc.Adhesive mortar is prepared in a clean 25 liter bucket where 25 kg of dry mix is slowly added to approx 5.5 liters of water and mixed using a paddle mixer to get a paste like consistency.

Approximately 4 kg of Adhesive mortar is applied on XPS using flat trowel and then ribbons are created using a notched trowel.

The INSUboard XPS is then fixed to wall in level and left undisturbed for 18 – 24 hours for sufficient bonding.

Holes are drilled in XPS boards and PVC fasteners are hammered to mechanically fix the boards.

On top of INSUboard, the prepared adhesive mortar paste is applied and simultaneously, glass fiber mesh is embedded in mortar. On the edges, a protection profile is installed to safeguard the edges and left to dry for 12 – 18 hours. Once it dries, top base of adhesive mortar is applied using flat trowel at approximate consumption of 4 Kg per sq.m. to achieve base mortar thickness of roughly 3 mm.

Final Finish: Once the top base mortar dries, final finishing can be done directly on it using texture paints , skim coat , emulsion paints etc.